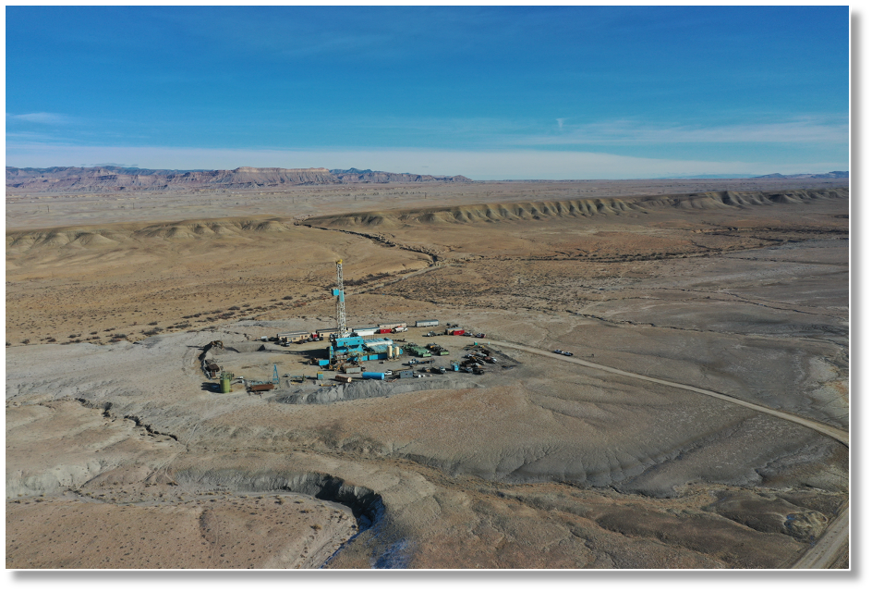

The Utah FORGE research team has achieved yet another major milestone in advancing enhanced geothermal system technologies with the successful completion of the first large scale 10-day stimulation trial (April 14-24, 2022) in the deep deviated well 16A(78)-32 (Video). Three intervals were tested in sequence at greater than 10,000 ft depth, including the open hole at the toe of the well (Stage 1), followed by two shallower 20 ft intervals that were lined with solid casing (Stages 2 and 3). In each stage, between 3000 and 4000 barrels of water were injected under pressure, causing pre-existing fractures in the reservoir to dilate and transfer heat to the injected cold water. After a 4-hour shut in, the hot injected water was produced back to the surface under controlled flow conditions. The stimulation trial ran according to schedule and plan, including the seamless deployment and retrieval of the bridge plugs at high pressures and temperature.

“This was an unprecedent technical success that resulted from more than a year of planning and the interaction of numerous researchers, vendors, the Department of Energy, industrial advisors, and service providers,” said Dr. John McLennan, co-principal investigator for Utah FORGE and a chemical engineering professor at the University of Utah. “It is a crucial step in the fifty-year journey to successfully develop an Enhanced Geothermal System.”

Conventional geothermal energy production relies on a trifecta of geologic conditions: heat at depth, open and conductive natural fractures, and an abundance of heated fluid. Yet these criteria only exist together in a small portion of the United States.

However, in an Enhanced Geothermal System, you can drill to modest depths and still reach adequate temperatures, and the other two elements — fractures and a heat transfer fluid (in this case, water) — can be engineered. Advancing EGS technologies will allow more of the country to develop geothermal resources. While it’s a simple enough concept, it has stymied researchers for half a century. For the commercial viability of EGS, the initiation, propagation and control of hydraulic fractures is imperative.

Data analysis and numerical modeling are ongoing at Utah FORGE. In late 2022 or early 2023, a second deep deviated well, the production well, will be drilled to intersect the hydraulic fractures. It will be drilled with the same trajectory directly vertically above the injection well, separated approximately by 300 ft. The connectivity of the fractures between the two wells will be established or improved, and short-term circulation testing will begin to assess the thermal viability of the geothermal reservoir.

To read more about the three-stage hydraulic stimulation of 16A(78)-32 please visit the Utah FORGE website.